Tunnel Excavator Rigging Lift

- By Bob DeLong

- Oct 20, 2009

Hanes Supply Recently Provided Solutions for this Tunnel Excavator Rigging Lift

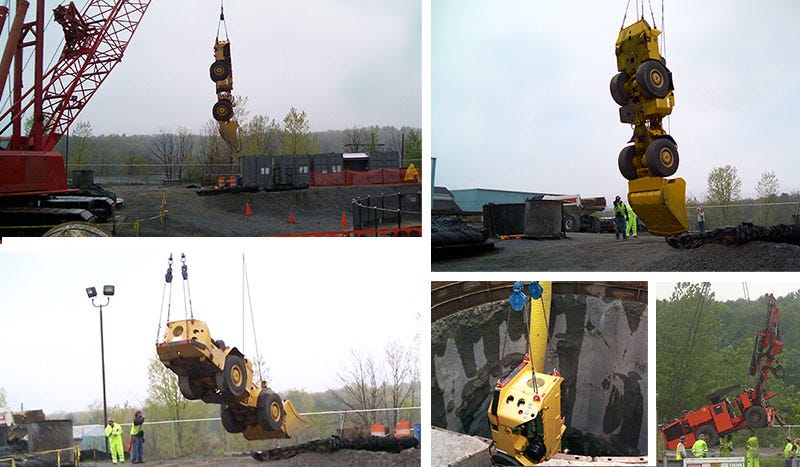

Hanes Supply, Inc. of Albany, was asked to advise the necessary rigging for a project to take a 38,900 lb Excavator turn it vertically and lower the unit down a 24’ diameter tunnel opening 200’ deep. The unit would be turned back to a horizontal position for excavation of rock debris at the bottom of the tunnel. We had to use all four pick points in the rear end of the Excavator to absorb the load equally. We had to meet the 70% safety factor of the rigging working load limits for MSHA standards while lowering the Excavator in tunnel.

The strength of the four pick points gave us only an extra 1,700 lb of more weight to handle during the lift than used. The list of items used were 2-15 ton 10” sheave snatch blocks, 2-105B7/8X x 12’ slings w/heavy duty thimble eyes in an inverted basket, 1-200HT1-1/4X x 6’ sling w/heavy duty thimble eyes, 1-200EH7/8X x 30’ slings w/slip hooks, and 6-8.5 ton shackles attached to the excavator pick points.

Hanes Supply, Inc, is always up for the opportunity to resolve your rigging challenges. This project was supported by Bob DeLong of Hanes Supply, Inc.

Please contact Hanes Supply for all your Sling and Rigging requirements.

Bob DeLong

Hanes Supply, Inc

PROJECT DETAILS

LOCATION

Albany, NY

DATE

October 2009

RIGGING

(2) 15 ton, 10" sheave snatch blocks

(2) 105B7/8X x 12' slings w/heavy duty thimble eyes

(1) 200HT1-1/4X x 6' sling w/heavy duty thimble eyes

(1) 200EH7/8X x 30' slings w/slip hooks

(6) 8.5 ton shackles

Hanes Supply, Inc. of Albany, was asked to advise the necessary rigging for a project to take a 38,900 lb Excavator turn it vertically and lower the unit down a 24’ diameter tunnel opening 200’ deep. The unit would be turned back to a horizontal position for excavation of rock debris at the bottom of the tunnel. We had to use all four pick points in the rear end of the Excavator to absorb the load equally. We had to meet the 70% safety factor of the rigging working load limits for MSHA standards while lowering the Excavator in tunnel.

The strength of the four pick points gave us only an extra 1,700 lb of more weight to handle during the lift than used. The list of items used were 2-15 ton 10” sheave snatch blocks, 2-105B7/8X x 12’ slings w/heavy duty thimble eyes in an inverted basket, 1-200HT1-1/4X x 6’ sling w/heavy duty thimble eyes, 1-200EH7/8X x 30’ slings w/slip hooks, and 6-8.5 ton shackles attached to the excavator pick points.

Hanes Supply, Inc, is always up for the opportunity to resolve your rigging challenges. This project was supported by Bob DeLong of Hanes Supply, Inc.

Please contact Hanes Supply for all your Sling and Rigging requirements.

Bob DeLong

Hanes Supply, Inc

PROJECT DETAILS

LOCATION

Albany, NY

DATE

October 2009

RIGGING

(2) 15 ton, 10" sheave snatch blocks

(2) 105B7/8X x 12' slings w/heavy duty thimble eyes

(1) 200HT1-1/4X x 6' sling w/heavy duty thimble eyes

(1) 200EH7/8X x 30' slings w/slip hooks

(6) 8.5 ton shackles

Klein® D2000-9ST 2000 Heavy Duty Rebar Work Cutting Plier, 9-3/8 in OAL

Klein® D2000-9ST 2000 Heavy Duty Rebar Work Cutting Plier, 9-3/8 in OAL

Stanley® FatMax® 33-716 Reinforced Tape Rule with BladeArmor®, 16 ft L x 1-1/4 in W Blade, Mylar® Polyester Film Blade

Stanley® FatMax® 33-716 Reinforced Tape Rule with BladeArmor®, 16 ft L x 1-1/4 in W Blade, Mylar® Polyester Film Blade

Channellock® 426 Tongue and Groove Plier, 7/8 in Nominal, 3/4 in L C1080 High Carbon Steel Straight Jaw, 6-1/2 in OAL

Channellock® 426 Tongue and Groove Plier, 7/8 in Nominal, 3/4 in L C1080 High Carbon Steel Straight Jaw, 6-1/2 in OAL

Estwing® E324S Framing Hammer, 16 in OAL, Smooth Surface, 24 oz Steel Head, Straight Claw, Steel Handle

Estwing® E324S Framing Hammer, 16 in OAL, Smooth Surface, 24 oz Steel Head, Straight Claw, Steel Handle

Mayhew™ 62065 X-Long Pin Punch Kit, Hex Shank, 9-1/2 in OAL, 5 Pcs

Mayhew™ 62065 X-Long Pin Punch Kit, Hex Shank, 9-1/2 in OAL, 5 Pcs

DeWALT® Power-Stud®+ Powers® 7449SD1-PWR Expansion Wedge Anchor, 3/4 in dia, 10 in OAL, 7-1/2 in L Thread, Carbon Steel, Zinc Plated

DeWALT® Power-Stud®+ Powers® 7449SD1-PWR Expansion Wedge Anchor, 3/4 in dia, 10 in OAL, 7-1/2 in L Thread, Carbon Steel, Zinc Plated

BBI® 777037 All Threaded Rod, 3/8-16, 12 ft OAL, Steel Alloy

BBI® 777037 All Threaded Rod, 3/8-16, 12 ft OAL, Steel Alloy

Primesource® 8CTDSKR Sinker Nail, 17/64 in, 2-3/8 in L, 9 ga, Vinyl Coated, Smooth Shank

Primesource® 8CTDSKR Sinker Nail, 17/64 in, 2-3/8 in L, 9 ga, Vinyl Coated, Smooth Shank

BBI® 754072 Medium Split Lock Washer, 1/2 in Nominal, 18-8 SS

BBI® 754072 Medium Split Lock Washer, 1/2 in Nominal, 18-8 SS