LIFTING DEVICE FABRICATION

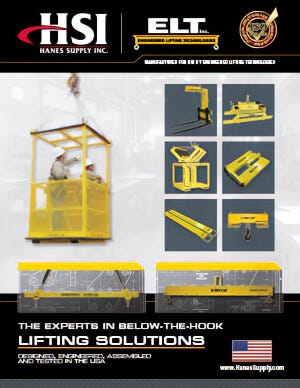

Hanes Supply offers both standard and custom American-made below-the-hook lifting devices. We provide lifters for various industries and applications; including construction, manufacturing, materials handling, steel and metal fabrication, cargo, and warehouse goods; as well as a patented lifting system as for the energy and wind tower erection industry.

Some lifts are challenging and require customized configurations to the lifting device. In addition to our wide range of stock lifting devices, we can customize lifters to fit length and headroom requirements for specific jobs.

For jobs that require special solutions beyond standard customizations, HSI partners with Engineered Lifting Technologies and their team of engineers to manufacture custom American-made lifting devices in their world class fabrication facility.

All of HSI’s lifting devices are built to exceed ANSI/AMSE B30 standards and OSHA compliance.

Keep your operations running efficiently and safely. We offer a wide variety of lifting devices designed to position loads easier and more ergonomically. With the proper material handling solutions, your warehouse, plant or jobsite will experience improved workflow and a reduction in downtime.

TRADITIONAL STOCK ITEMS AVAILABLE IN 7-10 BUSINESS DAYS:

- Fixed Spreader Beams

- Adjustable Spreader Beams

- Lifting Beams

- Personnel Crane Baskets

- Material Crane Baskets

- Skip Pans

- Coil Hooks

- Pallet Lifters

- Forklift Attachment Beams

- Forklift Fork Extensions

- Sheet Lifters

- Adjustable Windmill Staging Hooks

- Wind Turbine Lifting Brackets

- Windmill Hub Brackets

- Nacelle Lifting Beams

Have a special length requirement or headroom restrictions? Traditional lifters can be customized to address your application requirements. We can also engineer custom sizes and capacities. All customized lifters are built to exceed ANSI/AMSE B30 standards and are OSHA compliant.

Hanes Supply has full access to Engineered Lifting Technologies: A designer and manufacturer of custom below-the-hook lifting devices. We partner with ELT’s in-house team of engineers and fabricators to build American-made lifters for various industries and applications.

Your HSI sales representative will work with you and ELT’s engineering team to design your custom lifter to ensure it meets your specific needs and requirements before being released to the shop floor to be fabricated. ELT’s experienced engineers and skilled craftsman carefully monitor the project throughout all stages of the production process, resulting in a product that is built to exceed your expectations.

A Hanes Supply exclusive two-point top bracket pick for erecting wind turbines. This lightweight system is comprised of a set of two top-lifting brackets, two bottom-lifting brackets, SlingMax Twin-Path Slings®, shackles, bolts and a set of rigging plans. Wind experts agree that this system is the fastest and safest tower erection solution.

FEATURES AND BENEFITS:

- Exceeds ANSI/ASME requirements.

- Reduced manpower required to install.

- Durable nickel plated inserts.

- No load bearing welds.

- Reduced crane time.

- Tighter bolt clearance holes.

- Adjustable bolt pattern.

- Reduced number of brackets, only four needed for entire lift.

- Replaceable inserts to accommodate a variety of bolt patterns.

- Zinc dichromate plated body for outstanding corrosion protection.

- Each bracket weighs only 116 lbs.

Klein® D2000-9ST 2000 Heavy Duty Rebar Work Cutting Plier, 9-3/8 in OAL

Klein® D2000-9ST 2000 Heavy Duty Rebar Work Cutting Plier, 9-3/8 in OAL

Stanley® FatMax® 33-716 Reinforced Tape Rule with BladeArmor®, 16 ft L x 1-1/4 in W Blade, Mylar® Polyester Film Blade

Stanley® FatMax® 33-716 Reinforced Tape Rule with BladeArmor®, 16 ft L x 1-1/4 in W Blade, Mylar® Polyester Film Blade

Channellock® 426 Tongue and Groove Plier, 7/8 in Nominal, 3/4 in L C1080 High Carbon Steel Straight Jaw, 6-1/2 in OAL

Channellock® 426 Tongue and Groove Plier, 7/8 in Nominal, 3/4 in L C1080 High Carbon Steel Straight Jaw, 6-1/2 in OAL

Estwing® E324S Framing Hammer, 16 in OAL, Smooth Surface, 24 oz Steel Head, Straight Claw, Steel Handle

Estwing® E324S Framing Hammer, 16 in OAL, Smooth Surface, 24 oz Steel Head, Straight Claw, Steel Handle

Mayhew™ 62065 X-Long Pin Punch Kit, Hex Shank, 9-1/2 in OAL, 5 Pcs

Mayhew™ 62065 X-Long Pin Punch Kit, Hex Shank, 9-1/2 in OAL, 5 Pcs

DeWALT® Power-Stud®+ Powers® 7449SD1-PWR Expansion Wedge Anchor, 3/4 in dia, 10 in OAL, 7-1/2 in L Thread, Carbon Steel, Zinc Plated

DeWALT® Power-Stud®+ Powers® 7449SD1-PWR Expansion Wedge Anchor, 3/4 in dia, 10 in OAL, 7-1/2 in L Thread, Carbon Steel, Zinc Plated

BBI® 777037 All Threaded Rod, 3/8-16, 12 ft OAL, Steel Alloy

BBI® 777037 All Threaded Rod, 3/8-16, 12 ft OAL, Steel Alloy

Primesource® 8CTDSKR Sinker Nail, 17/64 in, 2-3/8 in L, 9 ga, Vinyl Coated, Smooth Shank

Primesource® 8CTDSKR Sinker Nail, 17/64 in, 2-3/8 in L, 9 ga, Vinyl Coated, Smooth Shank

BBI® 754072 Medium Split Lock Washer, 1/2 in Nominal, 18-8 SS

BBI® 754072 Medium Split Lock Washer, 1/2 in Nominal, 18-8 SS